-

2500 S Ann Arbor Ave, Oklahoma, OK 73128, USA

Greenhouse LED Grow Lights: Supplemental Lighting for Year-Round Production

Greenhouses let you grow with protection from wind, rain, and temperature swings, but they can’t “manufacture” sunlight when winter days are short or skies stay overcast. That’s where greenhouse LED grow lights become a practical production tool: they add predictable photons exactly when nature falls short, so you can keep quality and yield steady across seasons. Used correctly, supplemental LED lighting can turn “survive the winter” into “produce through the winter” while improving crop uniformity and planning reliability.

Table of Contents

What Greenhouse LED Grow Lights Actually Do

Supplemental lighting vs. photoperiod lighting

In greenhouse production, lighting usually serves one of two purposes. Supplemental lighting increases photosynthesis by adding usable light (PAR) to raise growth rate, yield, and quality, especially when natural light is low. Photoperiod (daylength) lighting is more about signaling—helping crops flower, stay vegetative, or avoid premature flowering by extending or interrupting the night.

Many growers combine both strategies. For example, you can use a low-intensity schedule to control flowering timing, then add higher-intensity supplemental light during critical growth windows to protect weekly harvest targets.

Why winter production is the toughest test

Winter creates a “double squeeze.” Light levels drop while heating and dehumidification needs rise, so every extra watt has to earn its place in the budget. Daily light integral (DLI)—the total photosynthetic light a plant receives in a day—often becomes the limiting factor for crop speed and finish quality during low-light months. Agri College

Why LEDs dominate modern greenhouse upgrades

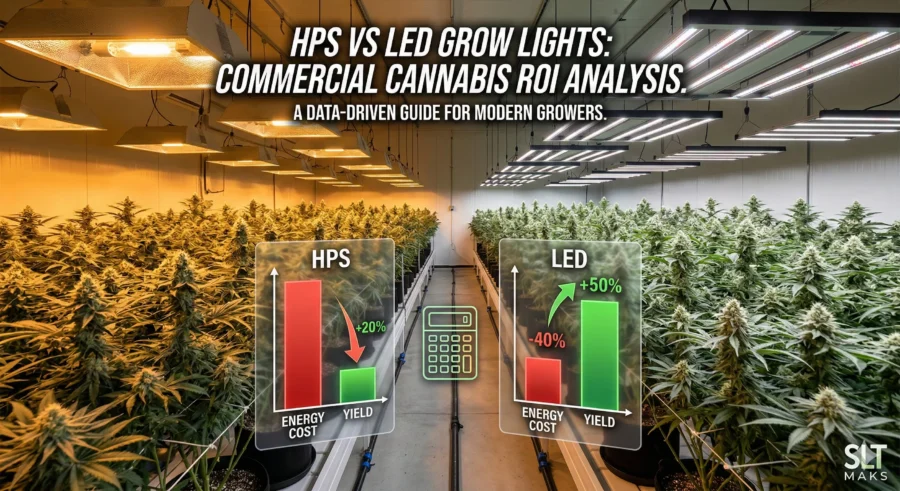

HPS helped greenhouse growers for decades, but LEDs bring advantages that matter in commercial planning: better electrical efficiency potential, easier dimming and zoning, more flexible fixture shapes (bars, slim top-lights, interlights), and less radiant heat dumped directly onto the canopy. Research comparing LED and HPS supplemental lighting in greenhouse settings has shown LEDs can match (and in some cases improve) plant outcomes when light intensity targets are met. ARS

Light Basics You Must Understand Before Buying Fixtures

DLI: the “daily budget” of plant-usable light

If greenhouse lighting feels confusing, start with DLI. DLI is measured as mol·m⁻²·d⁻¹, and it correlates strongly with growth, timing, and finish quality for many crops. Agri College

When you talk about year-round production, you’re really talking about hitting a DLI target consistently, even when sunlight is unreliable.

PPFD: how intense the light is right now

PPFD (µmol·m⁻²·s⁻¹) is instantaneous intensity at the canopy. It’s what you measure when you hold a quantum sensor under the lights. PPFD helps you design layout and uniformity, but DLI tells you whether the day’s total photons are enough.

PPF and PPE: output and efficiency

PPF (µmol/s) is how many photosynthetic photons the fixture emits. PPE (µmol/J) is the efficiency—how many photons you get per joule of electricity. This is the metric that lets you compare fixture performance in a greenhouse business case. DesignLights

Spectrum: “full spectrum” is a strategy, not a magic label

Most greenhouse crops perform well under broad “white + red” strategies, but spectrum still matters for morphology, flowering responses, and fruiting behavior. Practical spectrum decisions should be tied to your crop goals (compactness vs. stretch, vegetative speed vs. flowering timing, fruit yield and quality targets), not marketing terms. High-level research reviews explain how different wavebands influence photosynthesis and development, which is why controlled spectrum is valuable in commercial horticulture. Nature

Setting Realistic Targets by Crop and Season

Use DLI targets to define “enough light”

A helpful reference point is that moderate-DLI crops often target ranges like 14–18 mol·m⁻²·d⁻¹, while high-wire fruiting crops (e.g., tomato and cucumber) often target at least ~25–30 mol·m⁻²·d⁻¹ for strong performance. Agri College

Your local latitude, glazing type, shading, and seasonality determine how much of that target sunlight can realistically supply, and how much your greenhouse LED grow lights must cover.

Translate targets into supplemental PPFD

If you need to “build DLI” with lights, greenhouse practice commonly uses supplemental intensities in the range of ~60–200 µmol·m⁻²·s⁻¹, depending on crop and strategy. Agri College+1

For planning, many operations treat 60–100 µmol·m⁻²·s⁻¹ as common for moderate-DLI crops and 150–200 µmol·m⁻²·s⁻¹ as common for high-DLI crops, then refine based on measured sunlight and economics. Agri College

Don’t ignore photoperiod and scheduling constraints

Some crops respond strongly to daylength cues, and you may use lighting to extend daylength or interrupt night to manage flowering or vegetative growth. Cornell greenhouse lighting resources discuss how light timing can influence plant growth and morphology, which matters for propagation and finishing programs. Cornell Courses

In a year-round plan, confirm whether your main bottleneck is “not enough total photons” (DLI) or “wrong daylength signal,” because the solution and power costs differ dramatically.

Choosing the Right Greenhouse LED Grow Light System

Top lighting: the foundation for most commercial greenhouses

Top lighting is the most common approach for leafy greens, young plants, and many bench systems. The design priorities are uniformity, mounting height, minimal shading from the fixture itself, and electrical/control simplicity. A good top-light plan focuses on consistent PPFD distribution so your crop doesn’t become a “map” of bright and dim zones.

Interlighting: a tool for tall, dense canopies

In high-wire tomatoes and cucumbers, the canopy can become so dense that upper leaves capture most of the light while lower leaves become unproductive. That’s why interlighting (intracanopy lighting) exists—placing LED bars within the canopy to improve light penetration and leaf utilization. Wageningen University & Research has published work on hybrid and intracanopy lighting approaches in greenhouse vegetable production, including tomatoes and cucumbers. Wageningen University Research

Hybrid lighting: reduce risk and optimize canopy performance

Many large growers use hybrid strategies (top lighting plus targeted interlighting) to balance installation complexity, uniformity, and crop response. This approach is especially relevant when you’re upgrading an existing greenhouse and want predictable results without redesigning everything at once. Peer-reviewed literature and research summaries indicate supplemental LED strategies can improve tomato production outcomes, especially under low natural light periods. PubMed Central

Fixture spacing and quantity: start with a simple estimate, then measure

Before detailed simulations, you can do a rough “how many fixtures” estimate based on target PPFD and fixture photon output. Cornell extension guidance walks growers through estimating fixture count and electricity cost planning, which is a smart first step before requesting a full lighting plan. egrouni.com

After installation, measuring PPFD and logging DLI in-crop is what turns estimates into reliable production control.

Controls That Protect Yield While Cutting Power Costs

DLI-based control is the most grower-friendly logic

Instead of running lights at a fixed schedule all winter, many greenhouses run LEDs dynamically to “fill the DLI gap.” On brighter days, lights dim or shut off; on dark days, they run longer or stronger to hit the target. This aligns spending with plant need, not with the clock.

Zoning and dimming: buy photons where they matter

Greenhouses are not perfectly uniform environments. Edges, areas under structure, and zones near walls can run lower light, so separate zones and dimming help you correct weak spots without over-lighting the whole house. LEDs make this practical because they dim smoothly and can be controlled precisely.

Think in “cost per mol,” not just wattage

Electricity is paid in kWh, but crops respond to mol of photons, so your decision metric should connect the two. When you compare strategies, ask: “How many additional mol·m⁻²·d⁻¹ am I buying, and what does that do to crop timing and revenue?” Purdue extension materials emphasize analyzing the economic value of supplemental lighting rather than treating lighting only as a utility expense. Purdue University – Extension

Heat, Humidity, and Microclimate—The Greenhouse Reality Check

LEDs change heat distribution, not just the power bill

One reason LEDs feel different than HPS is heat placement. HPS systems emit more radiant heat downward, while LEDs generally reduce radiant load and may shift your heating/dehumidification strategy. That can be good for crop stress control, but it also means you should re-check setpoints, airflow, and condensation risk after switching technologies.

Manage humidity alongside lighting increases

More light often increases transpiration and growth, which can raise humidity if ventilation and dehumidification are not tuned. If your winter greenhouse already struggles with condensation, a lighting upgrade may require airflow improvements, better control logic, or a refined night strategy.

Shade curtains and glazing: don’t fight your own structure

Shade curtains, whitewash, and glazing choices affect how much sunlight reaches the crop and how much supplemental light is needed. Extension publications on DLI and greenhouse measurement emphasize how greenhouse materials and shading strategies change usable light at the canopy. ResearchGate

If you plan to run greenhouse LED grow lights heavily, confirm that your structure doesn’t unintentionally block the light you’re paying for.

ROI and Incentives—How Greenhouse LEDs Get Approved

LEDs can be eligible for utility incentives, but documentation matters

Many growers pursue rebates through efficiency programs, and those programs often require verified fixture performance. The DesignLights Consortium (DLC) horticultural lighting program publishes technical requirements and explains PPE and qualification thresholds used by many incentive programs. DesignLights

A practical takeaway is that your lighting supplier should be able to provide credible test data, warranty terms, and long-term performance information consistent with program expectations. Agri College

Your best payback levers are usually operational

In real greenhouse businesses, ROI is rarely “LEDs use X% less power” and that’s it. Payback is usually a combination of more consistent weekly harvest, fewer crop delays, better grade-out, improved scheduling confidence, and smarter operation of lighting hours against electricity pricing. The U.S. Department of Energy has analyzed energy savings potential of solid-state lighting (SSL) in agricultural applications, showing why efficiency improvements matter at scale. The Department of Energy’s Energy.gov

Crop response details can matter at scale

In fruiting crops, spectrum choices (including far-red strategy) can influence yield response under certain conditions. Recent peer-reviewed work has quantified yield responses of greenhouse tomato to different far-red fractions in supplementary lighting, showing that spectral tuning can be a measurable lever when done carefully. Frontiers

This doesn’t mean every greenhouse needs complex spectral recipes, but it does mean your lighting plan should be crop-specific rather than one-size-fits-all.

Installation and Purchasing Checklist for Greenhouse LED Grow Lights

Ask for the data that protects your decision

Before purchasing, request a complete spec package. At minimum, you want PPF, PPE, input power, voltage range, dimming method, thermal design approach, and recommended mounting height for your greenhouse geometry. You should also ask for photometric distribution or layout guidance so you can predict uniformity rather than hoping it “looks bright.”

Reliability is a financial metric

In year-round production, a lighting failure is not just a repair event—it’s a crop risk event. That’s why many qualification frameworks emphasize warranty length and light maintenance expectations over time, not just initial brightness. Agri College

For commercial operators, consistent output over seasons often matters more than chasing a tiny efficiency gain on paper.

Measurement after install is not optional

After installation, measure PPFD at multiple canopy points and log DLI over representative days. Michigan State University Extension materials explain DLI measurement concepts and why DLI strongly influences greenhouse crop performance. Agri College

If your measured data doesn’t match your target, adjust height, spacing, zoning, or schedule rather than guessing.

Why Choose SLTMAKS for Greenhouse LED Grow Lights

Built for commercial growers, not just hobby setups

At SLTMAKS, we think in the same metrics greenhouse operators use: PPFD, DLI, PPF, PPE, uniformity, and control strategy. That means you can discuss your crop targets and seasonal challenges in practical terms, then translate them into a lighting layout and operating plan that supports year-round production.

Flexible configurations for real greenhouse layouts

Greenhouses are rarely perfect rectangles with identical crops in every bay. We support greenhouse-focused fixture formats and can adapt configurations for top lighting, multi-zone layouts, and greenhouse environmental realities like humidity and cleaning routines. When your goal is dependable supplemental lighting—not just “more light”—those details matter.

A process that starts with your production goal

If you tell us your crop type, greenhouse dimensions, location/seasonality, and your target (yield increase, cycle-time reduction, propagation quality, or winter continuity), we can help you map that into a supplemental lighting approach that makes operational sense. The end goal is simple: greenhouse LED grow lights that behave like a controllable production input, not a guessing game.

FAQ

How many hours per day should I run greenhouse LED grow lights?

It depends on your target DLI and how much sunlight your greenhouse receives that day. A DLI-based approach is often more cost-effective than a fixed schedule because it adjusts lighting hours to actual conditions. Agri College

What PPFD should I aim for in supplemental lighting?

Many commercial greenhouses operate supplemental PAR levels roughly in the 60–200 µmol·m⁻²·s⁻¹ range, with higher values more common for high-DLI fruiting crops. Your exact target should align with crop DLI goals and economics. Natural Resources Conservation Service

Are LEDs always better than HPS for greenhouses?

Not automatically, but LEDs offer strong advantages in controllability and fixture design, and research shows comparable crop quality outcomes when intensity targets are met. The best choice depends on your greenhouse heating strategy, electricity pricing, and retrofit constraints. ARS

Do I need “full spectrum” for greenhouse crops?

Most crops do well when the lighting strategy supports adequate PAR and appropriate developmental signals. Spectrum tuning can be a performance lever, but it should be tied to crop goals and validated results rather than labels. Nature

Can supplemental LEDs really help year-round tomato or cucumber production?

Yes, especially in low-light seasons and higher latitudes where sunlight alone can’t support high yields consistently. Research institutions have published work on supplemental and hybrid LED strategies for greenhouse vegetable production, including tomatoes. Wageningen University Research

Make Light a Controllable Input, Not a Seasonal Risk

Year-round greenhouse production is built on consistency, and consistency starts with controlling the variables you can—especially light. With the right greenhouse LED grow lights, correct targets (DLI/PPFD), and smart control, you can stabilize crop timing, protect quality, and plan production with far less seasonal uncertainty. If you want, tell me your greenhouse size, crop type, location/latitude, and winter production goal, and I’ll draft a practical supplemental lighting target plan (PPFD, photoperiod, and control logic) you can use for your SLTMAKS landing page and sales workflow.